PANCAKE COIL

In the past few years there has been a steady rise in the consumption of copper tubes in ACR systems. Our Pancake coils are typically used for installation in ACR systems. Nippon’s pancake coils are also used in the manufacturing of ACR appliances by OEM’s, which we provide in bright annealed form with a mirror finish.

Our pancake coils are single layered which makes it easily transportable with economical packaging. Totally controlled furnace is designed and equipped in such a way to maintain the pancake copper coils’ shape as it is annealed, minimising any coil distortion. Nippon also provides these pancake coils with PVC coating as per clients’ requirements, which makes it capable to with stand high temperatures (upto 110*C) and is easily flexible and elastic at low temperatures (upto -60*C).

COPPER PIPES & TUBES FOR VRF AIR CONDITIONING APPLICATION

Nippon is a prominent manufacturer of copper and copper based alloys known worldwide for its high grade quality and on time services. Copper tubes are available in hard drawn straight lengths and bright annealed pancake coils which are manufactured as per international and national clients’ requirements.

Wide range of products are used in ACR applications which complies with ASTM specifications. At Nippon, all the copper pipes and coils are checked for chemical composition, temper, tolerance, cleanliness, 100 % carbon free to maintain the quality and trouble free usage.

COPPER STRAIGHT LENGTH (HARD/SOFT)

Nippon’s Copper pipes and tubes are extensively used in ACR systems, heat exchanger systems, and gas and water transportation.

Growing industry demands, stringent operating conditions, demand for high operating efficiency and elimination of harmful emissions have led to renewal in interest of copper tubes. Also its light weight and ability of prefabrication has led to increase in its demand.

We at Nippon provide various sizes of straight tubes as per clients requirements. Nippon copper tubes are ideal products for hot/ cold water, central heating and gas service installations due to its ease of bending, lightweightedness and its ability to withstand high internal pressures.

COPPER TUBES FOR AUTOMOBILE INDUSTRIES

Nippon’s copper pipes and tubes for automobile industry have countless advantages over other metals. Copper is easily bendable, has high corrosion resistance and has been proved to have many other outstanding attributes.

Today’s generation’s demand for transportation is growing rapidly which asks for advancements in the systems with high quality services. The automobile industry has realised that copper is one of the best metals and it’s durability, efficiency and immaculate quality makes it perfect for application in vehicles.

COPPER TUBES FOR MARINE APPLICATIONS

Nippon produces the best copper tubes and pipes which can be widely utilized for seawater systems designed for outstanding resistance to biofouling and other magnificent properties. Copper has very low reactivity series which means it doesn’t tend to corrode.

Copper alloys can resist saline solutions, alkaline solutions and various organic solutions. Though copper alloys are susceptible to rapid attack when in contact with oxidizing acids, oxidizing heavy metal salts, sulphur, ammonia and sulphur and ammonia compounds.

COPPER PIPE FOR MEDICAL GAS PIPELINE

Nippon’s Med copper tubing is available in a variety of lengths, and sizes of both Type L and Type K. Our copper pipes for medical gas piping can withstand high pressure and corrosion. It is durable, easily installable and meets all the global standards and requirements of medical gas piping applications.Nippon provides 100% safe and low maintenance copper pipes ensuring trouble free performance for years.

COPPER PLUMBING TUBE

Nippon copper plumbing tubes are reliable, leak proof, durable and have very low maintenance thus are cost saving and advantageous. Nippon plumbing pipes resist corrosion, installer friendly and require no threading. Plumbing tubes are offered in various different standards and customised specifications.

The BS 2871 specifies 3 wall thickness suitable for hot and cold water installations under Table X, Y & Z. Table ‘X’ is the table normally used for plumbing and gas. Tubes are 100% eddy current tested. Mechanical and chemical properties meet the standards of BS 2871, Part 1:1971 or the EN:1057. Tube sizes range from 12 mm to 159 mm. The standard plumbing sizes are (in mm): 15, 22, 28, 35, 42, 54, 66.7, 76.1, 108, 133 & 159. These include types K, L, M and DWV. All tubes supplied to these ASTM standards are a minimum of 99.90 percent pure copper.

COPPER TUBES FOR GENERAL ENGINEERING

Copper tubes manufactured at Nippon can be used for general engineering, in residential as well as corporate buildings, and the drainage piping is straight forward in design and can be easily installed. DWV copper installed with good engineering and experienced workers leads to countless years of stress free functioning.

Copper tubes are preferred for General Engineering due to their thermal and electrical conductivity, malleability, high resistance to corrosion and strength. We at Nippon manufacture and export our copper tubes all around the globe.

COPPER FITTINGS

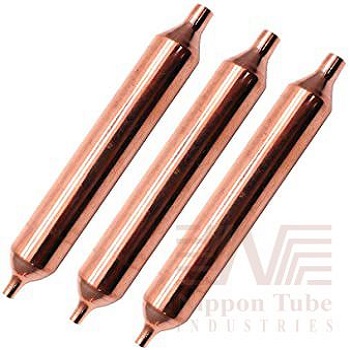

Accumulators

ACR Muffler

Adapter

C Bend

Coupling

Cross Bend Full Crossover

Cross Fittings

Crossover

Degree Elbow 45

Degree Elbow 90

Strainers

Side Open

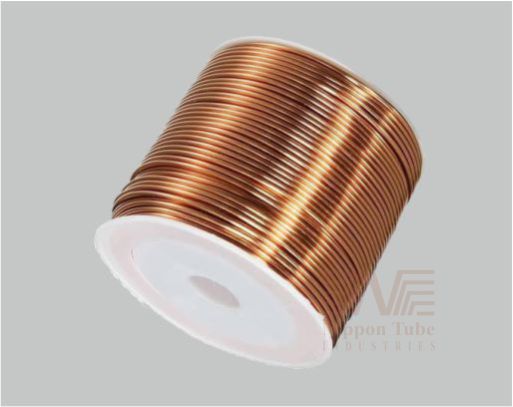

LEVEL WOUND COPPER COIL

We import and supply our LWCs from MetTube products wherein all LWC coils are produced as per the ASTM and Coproclima specifications. All these specifications were prepared in order to take care of the Indian ACR industry. Every mm of the copper pipe is 100% Eddy current tested and surface defects found are marked by black colour.

In case of heavy coils, LWC copper tubes are wounded in Jumbo coil form as per the customers requirement. The whole copper tube is cleaned with nitrogen and in order to protect the coil from internal oxidation during large transportation tube ends are sealed using plastic end caps.

Nippon delivers LWC coils with cardboard reels in order to protect it from any sort of damage. These coils are especially suited for long production runs for industrial application which is widely applied in ACR and Heat Exchanger field. Level Wound Copper Coils are usually supplied in soft and light annealed form, whereas LWCs can be ordered in hard drawn temper as well depending on the customers requirement.

FINNED TUBES

Nippon Tube Industries are one of the leading suppliers of various different types of finned tubes applicable in the cooling or heating transfer systems. Finned tubes get improved heat transfer as compared to the plain tubes which allows reduction of size and weight of the heat exchanger and condensers. At Nippon Finned tubes are available in straight length with plain ends on both the sides which is also available with interim skip as per clients requirements.

PVC COATED COPPER TUBES

Nippon provides high quality PVC tubes and copper coils designed to protect against aggressive environment and colour coded for easy identification.

PVC coating that is stringently extruded onto the tube by Nippon is available in blue, black, yellow and green further supplied as per customer requirements.

Copper tubes manufactured by Nippon meet the specifications of international standards such as ASTM-B-75/68 and UNS C12200. Pressure drop test is conducted once the PVC coating ( as per ASTM-D-1047) is done onto the copper tube to ensure that the tubes are leak proof.

COPPER CAPILLARY TUBING

Nippon’s Copper Capillary Tube is widely used for a range of applications : Refrigeration and Air Conditioning appliances, Heat Transfer Tube (Thermostat, Heat Pipe), Gas Appliances, Fire Alarm Systems, Coaxial Semi-Rigid Cable, Solderless Terminals, Water Tube service and Distribution, Chemical industry, Thermal conductivity temperature control device, and many more.

Copper Capillary Tube is a long, narrow tube of constant diameter. Our group of competent engineers develop and improve our products using specially designed advanced equipment to meet the special needs of our clients.